Gravity grease separators

Purpose

Gravity grease separator is a device used to remove grease from wastewater. It can be used as a front-end equipment before wastewater treatment plants or separately before the junction of wastewater containing fat (waste water from meat plants, from the kitchens of restaurants, etc.) into drains.

Process

In the gravity grease separator separation occurs only on the basis of the physical properties of fats (density less than the density of water). Waste water flows into the grease separator, which leads to cooling and due to different densities to flotation fat particles of fat on the surface. Separate floating grease is collected manually.

Design description

Gravity grease separator is a plastic tank provided with inside built-in equipment (plastic partitions).

LT

|

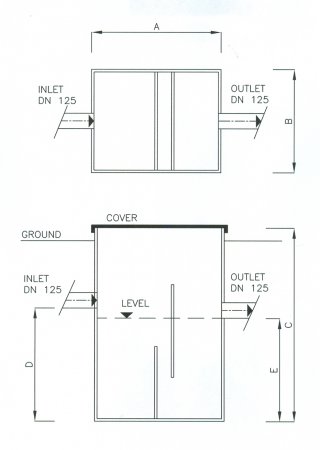

Structural Drawing

Structural drawing LT

|

Basic Specifications

| Type | Capacity |

Dimensions A x B x C |

Height of inlet D |

Height of outlet E |

Accumulation of grease | Piping |

| l/s | m | m | m | mm | ||

| LT 2 | 2 | 1x0,8x1,5 | 0,9 | 0,8 | no | 125 |

| LT 3 | 3 | 1,25x1x1,5 | 0,9 | 0,8 | no | 125 |

| LT 4 | 4 | 2x1,16x1,58 | 1,18 | 1,08 | no | 125 |

| LT 4-A | 4 | 2x1,66x1,58 | 1,18 | 1,08 | yes | 125 |

Advantages

Removal of fat from wastewater significantly reduces substance load of wastewater entering the treatment plant. It allows to reduce the size of treatment plant aeration tanks, has less demands on attendance, less production of excess sludge, etc.

Gravity grease separator ensures high reliability of operation, almost zero operating costs and very simple operation at a satisfactory efficiency of the equipment.